- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

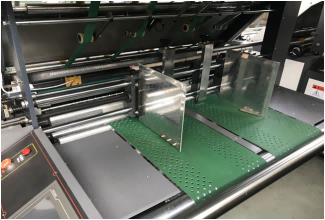

Semi-automatic flute low table servo paper mounting machine corrugated carton machinery flute laminator machin

- group name

- Fully automatic flute laminating machine

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- 1300

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 15:50:27 GMT

Paramtents

color black

Max size of cover face 1300X1250mm

Mix size of cover face 400mmX400mm

Top paper thickness 140-800g

Bottom sheet thickness 2/4 ply A/B/C/E/F Flute

Machine speed 0-100m/min

Precision ±1mm

Power 7kw

Size 8m x 2m x 2.9m

Weight About 2500kg

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

■ The face paper is humanized design with artificial front propulsion, and the paper feeding table is raised to make the paper feeding easier, and the bottom paper is convenient, and the efficiency is higher; ■ The bottom paper adopts servo automatic feeding, according to the speed of manual feeding paper, automatic and continuous tracking. ■ New concept before the specified position, high positioning accuracy, the base paper does not lead; Paper lead adjustable; ■ Measuring roller linear speed scientific design, uniform glue quantity, avoid high speed operation of glue; ■ Imported electrical components to ensure the stable operation of the circuit system. PLC tracking technology, automatic fault alarm;

※Technical parameters

Model | 1300HI | 1600HI |

Max size of cover face | 1300X1250mm | 1600X1250mm |

Mix size of cover face | 400mmX400mm | 400mmX400mm |

Top paper thickness | 140-800g | 140-800g |

Bottom sheet thickness | 2/4 ply A/B/C/E/F Flute | 2/4 ply A/B/C/E/F Flute |

Machine speed | 0-100m/min | 0-100m/min |

Precision | ±1mm | ±1mm |

Power | 7kw | 7kw |

Size | 8m x 2m x 2.9m | 8m x 2.3m x 2.9m |

Weight | About 2500kg | About 3000kg |