- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

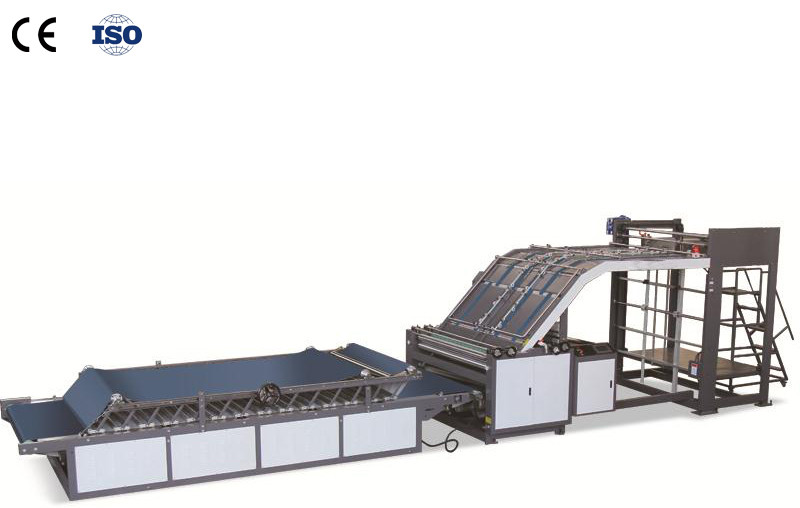

Semi-automatic flute laminating machine 1300type

- group name

- Fully automatic flute laminating machine

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- 1300

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 14:00:23 GMT

Paramtents

color black

Max size of cover face 1300X1250mm

Mix size of cover face 400mmX400mm

Top paper thickness 140-800g

Bottom sheet thickness 2/4 ply A/B/C/E/F Flute

Machine speed 0-100m/min

Precision ±1mm

Power 9 kw

Size About 3000kg

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

※Technical parameters

Model | 130HII | 1600HII |

Max size of cover face | 1300X1250mm | 1600X1250mm |

Mix size of cover face | 400mmX400mm | 400mmX400mm |

Top paper thickness | 140-800g | 140-800g |

Bottom sheet thickness | 2/4 ply A/B/C/E/F Flute | 2/4 ply A/B/C/E/F Flute |

Machine speed | 0-100m/min | 0-100m/min |

Precision | ±1mm | ±1mm |

Power | 9 kw | 9 kw |

Size | 10m x 2m x 2.9m | 10m x 2.3m x 2.9m |

Weight | About 3000kg | About 3500kg |