- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

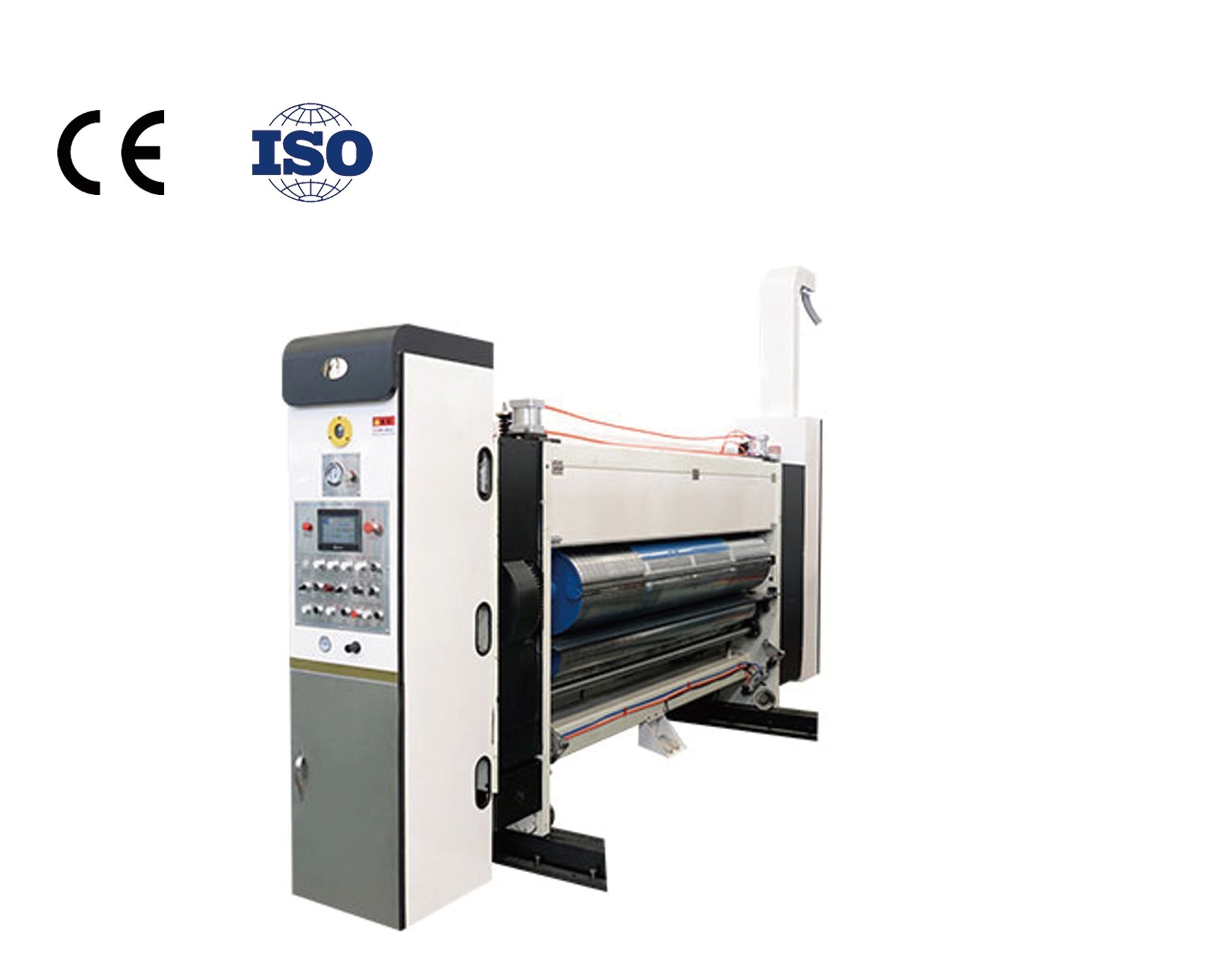

Hengchuangli automatic printing machine series model 1228 for carton printing die - cutting Fully Automatic Carton and Pizza Box Printing Mach

- group name

- Printing machinery

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- 1228

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 15:37:38 GMT

Paramtents

color gray

Maximum speed (piece/min) 230

Paper feeding precision (mm) ±1.0

Maximum feed size (mm) 1200x2900

Minimum feed size (mm) 350x600

Size of drawing paper (mm) 1500x2500

Maximum printing area (mm) 1200x2800

Printing set (mm) ±0.5

Thickness of standard printing plate (mm) 7.2mm

Minimum slotting interval (mm) Positive knife 130x130

Minimum slotting interval (mm) Scalpel 230x65

Maximum groove depth (mm) 300

Slotting accuracy (mm) ±1.5

Die cutting precision (mm) ±1.0

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Fully Automatic Carton and Pizza Box Printing Mach

Main featrues:

Paper feeding unit:

Printing unit:

Slotting device:

Die cutting unit:

· Master computer and unit man-machine interface control.

· Pneumatic tooth gap lock device, die cutting pressure electric and setting adjustment.

· The guide wheel moves quickly, the gap is electric, and the setting is adjusted.

· Automatic roller mechanism for rubber pad roller, imported quick change rubber pad and rubber pad grinding correction mechanism.

· Master computer and unit man-machine interface control.

· Pneumatic tooth gap lock device, die cutting pressure electric and setting adjustment.

· The guide wheel moves quickly, the gap is electric, and the setting is adjusted.

· Automatic roller mechanism for rubber pad roller, imported quick change rubber pad and rubber pad grinding correction mechanism.

Accurate "set" speed difference compensation system to ensure die cutting accuracy and wide compensation range.

Die cutting unit: