- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

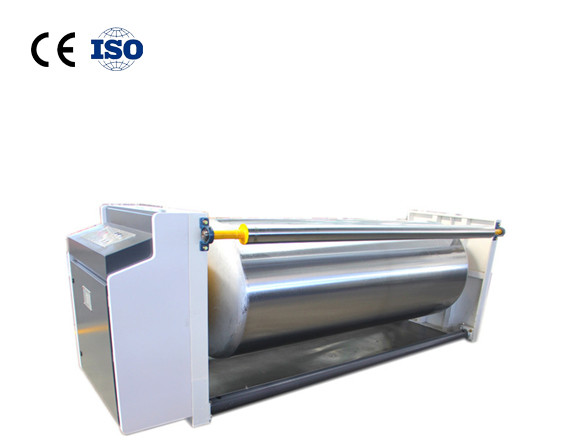

2-layer corrugated board production line / food packaging carton production machine WJ-150-1600 corrugated paper box corrugated carton produ

- group name

- 2ply Corrugated Cardboard Production Line

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- 320C

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 15:25:27 GMT

Paramtents

Design speed: 150m/min

Effective width: 1600mm

Leng xing A, B, C and E. 。

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

corrugated paper box corrugated carton produ

The spindle¢240mm,hyperbola heavy rocker,toothed chuck,multi-disc ventilated disc brakes,hydraulic drive lift,left and right translation,for medium。

Rail length 6000mm,trolley used 10mm plate welding。

roller¢900mm,including certificate of pressure vessel。Electromotion adjustment angle。

It adopts cover suction structure and is equipped with high-pressure strong fan. The air source and electrical control are centralized in the same operation cabinet, and the operation side is fully enclosed and covered. High quality resin sand casting, wall panel thickness 200mm. A lifting trolley is installed on the conveying overpass, which can be used to take out the tile roller assembly and pressure roller when necessary, which is convenient and fast. The gluing roller unit adopts an integral outward moving structure, which can be moved out of the machine as a whole during maintenance, so as to improve the work efficiency. The spray and humidity control devices are equipped to maintain good deformation stability and avoid dry cracking. It adopts automatic circulating glue supply system and double pneumatic cylinder pneumatic glue feeding device, which has good cushioning effect.

Independent frequency motor drive lifting, transmission。Main beam is connected with the 20th channel, 16-beam, No. 63 angles, columns, etc. Both sides of the security fence, the word pedals, ladders。

AC servo control spiral knife structure,Touch screen display。Collect paper machine adopting a classification adjustable count output cardboard,The maximum length of stacking is 1.3 meters.pull paper feed and transverse motor is all frequency speed control,NC thin knife slitting 5 group blades。Spiral knife Crosscutting.