- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

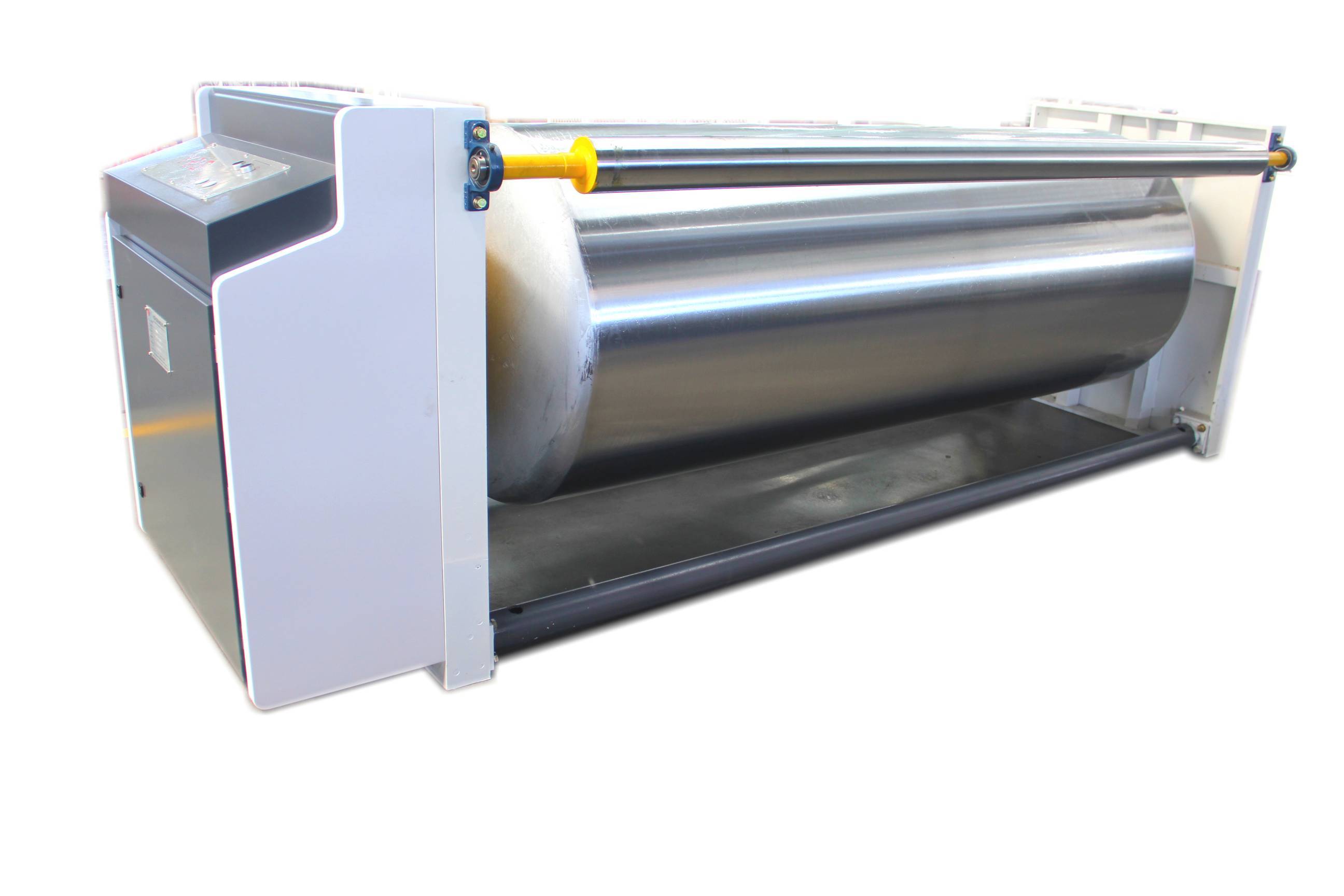

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

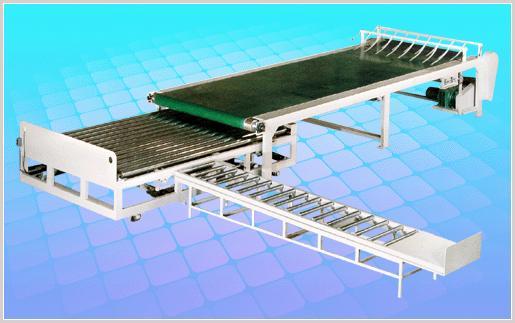

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

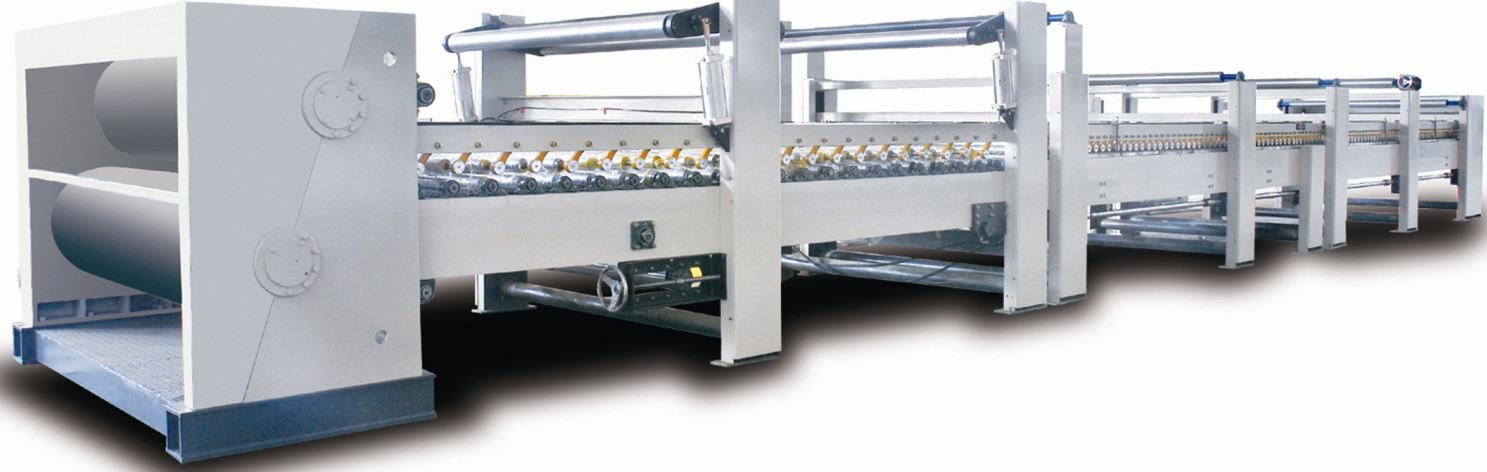

Carton machinery high speed corrugated board produ Fully Automatic 5 ply corrugated board production line

- group name

- 5 ply Layer corrugated board production line

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- WJ180-2200 -II

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 15:22:27 GMT

Paramtents

Maximum paper width 2200mm

Working speed 180 m/min

Longitudinal cutting paper accuracy ±1mm

Crosscutting precision ±1mm

Corrugated combination A\C\B\E

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

The diameter of the roller is 215mm.Independent inverter motor drive per layer.Manual adjustment of glue clearance

ZQS Thin knife slitting

Electric thin knife, electric tuning, five-blade eight-wire, blade with tungsten alloy steel.

NC cutter helical knives

Full Ac servo control, energy storage brake, helical knife type structure, oil-immersed gear drive, 10.4-inch touch screen display.

Electric adjusting board dimensions, pneumatic control horizontal output board.