- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

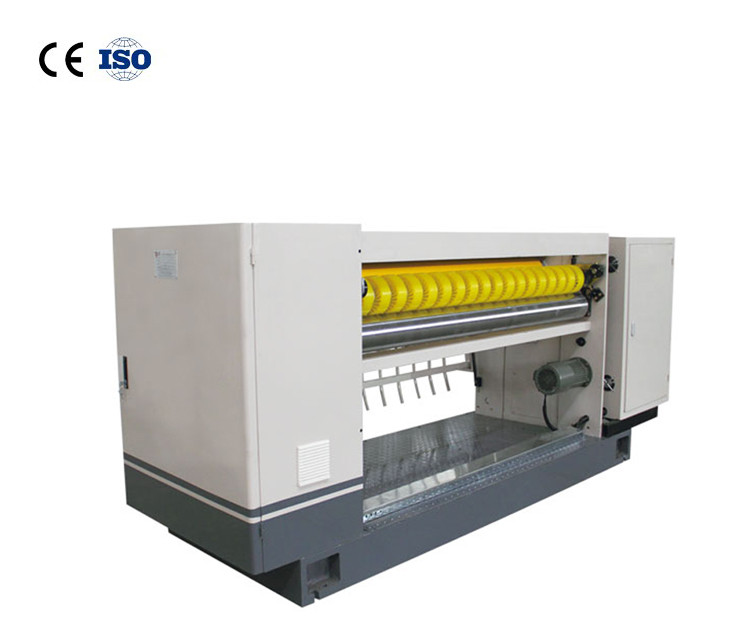

Nc-200 high efficiency spiral knife crosscutting machine is suitable for corrugated board production line

- group name

- Corrugating Machine Slitter Scorer

- Min Order

- 1 piece

- brand name

- Jumbo Corrugated Machinery Solution

- model

- NC-30D

- Nearest port for product export

- Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- PayPal, Westem Union

- update time

- Sat, 09 Oct 2021 08:03:49 GMT

Paramtents

Design speed 200m/min

width of cloth 1400mm

cutting length 500mm-9000mm

Cutting accuracy ±1mm

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

It can store 200 units orders,replace the cutter specifications quickly and accurately,changing orders without stop,And enables networked computers to facilitate production management.Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy。Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life。Around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage。This type of brake is energy storage type (non-energy brake), so in the process of production, the average power consumption is 1 / 3 of that of the ordinary NC cutting machine, saving more than 70% of electricity and achieving the goal of saving money.Exact and adjustable no gap gear to ensure precise blade engagement, running balance.Independent oil pump and filter are used to distribute two sets of copper pipes in each gear position to feed oil, lubricate and cool.Knife roller: fine quality forged steel material, the balanced, with good stability.