- Home

- About us

- Products

- Corrugating Machine Single Facer

- Corrugating Machine Double Facer

- Mill Roll Stand

- Corrugating Machine Slitter Scorer

- NC Cut Off Machine

- Corrugating Machine Preheater

- Corrugating Glue Machine

- Corrugating Bridge Tension Correction Machine

- Corrugating Machine Cardboard Stacker

- Corrugating Machine Automatic Paper Splicer

- Glue Making Machine

- Paper Sheet & Side Conveyor Machine

- 5 ply Layer corrugated board production line

- 3 ply layer corrugated board production line

- 2ply Corrugated Cardboard Production Line

- Printing machinery

- Box gluing machine series

- Fully automatic flute laminating machine

- Faqs

- News

- Certificate

- Contact us

What is corrugated cardboard production line?

time2021/02/08

- Corrugated board production line is the most important production line equipment in carton packaging enterprises, including wet end equipment, cadre equipment, production management system...

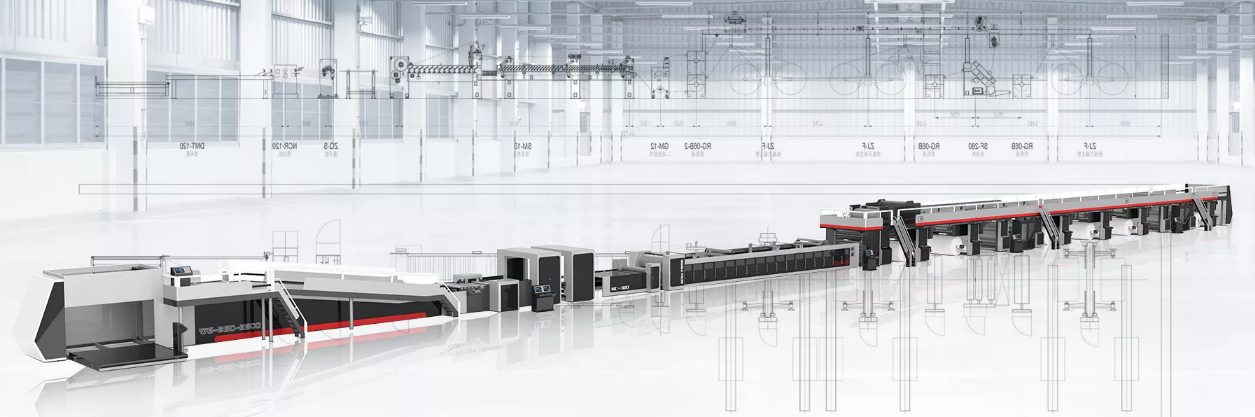

Corrugated board production line

The abbreviation of the corrugated board production line is a streamlined operation line composed of corrugated rolls, gluing, bonding, dividing and pressing, cross-cutting into specifications cardboard, and finally yard output.

The corrugated board production line consists of two relatively independent process sections, wet end equipment and dry end equipment.

Among them, the wet end equipment mainly includes base paper trays, automatic paper splicing machines, preheating pre-adjusters, single-sided corrugating machines, paper flyovers, glue spreaders, double-sided machines, etc. The wet end equipment makes the corrugated base paper into three, five and seven layers of corrugated cardboard with different flute type combinations.

Cadre equipment mainly includes rotary cutting machine, slitting and creasing machine, cross-cutting machine, stacking machine, etc. The cadre equipment performs slitting, creasing and stacking of corrugated cardboard according to the order requirements.

We can design the most suitable production line for you according to your site and budget needs.

Related Products